The Comprehensive Guide to Concrete Aluminum Slab Formwork

Revolutionizing Slab Construction: The Comprehensive Guide to Concrete Aluminum Slab Formwork

Introduction: The Efficiency Imperative in Modern Construction

In today's fast-paced construction landscape, where project timelines are compressed and sustainability requirements are heightened, the choice of formwork systems has emerged as a critical determinant of success. Among the innovative solutions transforming concrete construction globally, **aluminum slab formwork systems** stand out as a game-changing technology. These systems are redefining efficiency, precision, and economic viability for **concrete slab construction** projects worldwide, offering international contractors and developers a compelling alternative to traditional timber and steel systems.

This article provides B2B buyers with a comprehensive analysis of aluminum formwork technology, examining its market position, technical advantages, application processes, and future trends to inform strategic procurement decisions.

Market Landscape: The Rising Dominance of Aluminum Formwork Systems

Recent market analysis from Technavio indicates the global aluminum formwork market is projected to grow by USD 1.87 billion during 2023-2027, accelerating at a CAGR of 5.25%. This growth is particularly pronounced in regions with intensive infrastructure development and high-rise residential construction, including Southeast Asia, the Middle East, and North America.

The economic rationale is clear: formwork typically accounts for 35-40% of total concrete construction costs. By implementing reusable aluminum formwork systems, contractors can distribute the initial material investment across hundreds of construction cycles while achieving significantly faster floor cycle times—often reducing slab construction schedules by 30-40%. For projects with repetitive floor plans, such as residential towers, hotels, and institutional buildings, modular aluminum formwork has transitioned from a specialized solution to a mainstream methodology for enhancing return on investment.

Technical Advantages of Aluminum Slab Formwork Systems

Superior Strength-to-Weight Ratio and Precision

Manufactured from high-grade aluminum alloys (typically 6061-T6), **aluminum formwork panels** offer exceptional strength while remaining remarkably lightweight. This characteristic enables easier handling, faster installation, and reduced labor requirements compared to steel alternatives. The extruded aluminum components maintain dimensional stability across temperature variations, ensuring consistent **concrete slab flatness** and superior surface finish that often eliminates the need for additional ceiling plastering.

Unparalleled Construction Speed and Labor Optimization

The modular design of **aluminum slab formwork systems facilitates rapid assembly through simple pin-and-wedge connections. Skilled crews can achieve installation speeds 2-3 times faster than conventional timber formwork. Integrated **early striking systems** allow the removal of formwork panels while leaving supporting props in place, enabling quicker reuse and dramatically shortening floor-to-floor construction cycles. This accelerated timeline directly translates to reduced overhead costs, earlier project completion, and improved cash flow—critical advantages in competitive markets.

Lifecycle Economics and Sustainability Credentials

While the initial investment in **aluminum formwork for concrete slabs** exceeds that of timber, the total cost of ownership reveals a different story. With potential reuse exceeding 500 cycles with proper maintenance, the per-use cost becomes economically marginal. From an environmental perspective, aluminum formwork supports circular economy principles: it is 100% recyclable at end-of-life, generates minimal site waste compared to disposable timber forms, and reduces embodied carbon through repeated reuse. These attributes make it an ideal solution for projects pursuing LEED, BREEAM, or other green building certifications.

Application Process: From Design to Installation

Digital Design and Manufacturing Precision

Modern aluminum slab formwork projects begin with comprehensive BIM modeling, where every component is digitally planned and coordinated. This virtual design and construction (VDC) approach minimizes onsite conflicts and ensures optimal material utilization. Components are then precision-manufactured in controlled factory environments using advanced extrusion and CNC cutting technologies, guaranteeing millimeter-perfect tolerances.

Streamlined Onsite Workflow

The onsite installation process follows a systematic methodology:

1. Layout and Preparation: Crews position soffit beams and drop-head props according to grid markings.

2..Panel Installation: Workers assemble pre-numbered aluminum panels using simple connecting devices, creating the complete slab decking system.

3.Quality Verification: The system is checked for alignment, level, and cleanliness before concrete placement.

4. Concrete Placement: The non-porous aluminum surface produces smooth concrete finishes with minimal grout loss.

5. Striking and Reuse: After achieving specified concrete strength, panels are easily detached and transferred to the next floor, while supporting elements remain temporarily.

This repetitive, efficient cycle enables projects to achieve consistent **fast-track construction** schedules with predictable resource allocation.

Future Trends: Digital Integration and Advanced Applications

The next evolution of **aluminum formwork technology** incorporates digital innovation and expanded applications. Smart formwork systems with embedded sensors can monitor concrete curing in real-time, while RFID tagging enables automated inventory tracking. Additionally, hybrid systems combining aluminum with engineered plastics are emerging for curved or architectural concrete applications. The integration of **aluminum formwork** with prefabricated MEP systems and insulation panels represents another frontier, pushing toward more complete prefabricated construction solutions.

Frequently Asked Questions (FAQ)

Q1: How does the initial cost of aluminum formwork compare to other systems, and what determines the payback period?**

A: The initial investment for aluminum formwork is typically 2-3 times higher than disposable timber but comparable to or lower than heavy-duty steel systems. The payback period depends on project scale and repetition—generally achieved within 3-5 projects of similar design. The true economic advantage lies in total project savings: reduced labor costs (40-60% fewer carpenters), shortened project duration (20-30% faster), and elimination of ongoing material purchases.

Q2: Can aluminum formwork accommodate complex slab geometries or custom architectural features?**

A: While most efficient for repetitive layouts, modern systems offer considerable adaptability. Manufacturers provide customized components for slab edges, drop panels, and openings. For highly complex geometries, hybrid approaches combining standard aluminum panels with supplementary timber or CNC-cut components often provide the optimal balance between efficiency and flexibility.

Q3: What maintenance is required to achieve maximum reuse cycles from aluminum formwork?**

A: Proper maintenance includes regular cleaning after each use (removing concrete residue with non-abrasive tools), immediate repair of damaged components, and proper storage in organized racks.

Most reputable suppliers offer maintenance training and spare parts support to maximize system lifespan.

Q4: How does aluminum formwork perform in extreme climatic conditions, particularly coastal environments?**

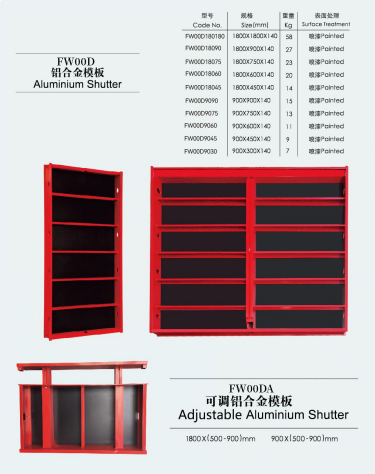

A: High-quality aluminum formwork undergoes specialized surface treatments (anodizing or powder coating) that provide excellent corrosion resistance. Unlike steel, aluminum forms a protective oxide layer when exposed, preventing progressive rusting. In aggressive environments, additional protective coatings can be applied, and regular cleaning to remove salt deposits is recommended.

Conclusion: Strategic Implementation for Competitive Advantage

The transition to aluminum slab formwork systems represents more than a mere material substitution—it embodies a strategic commitment to construction excellence. For international contractors and developers, adopting this technology translates to predictable scheduling, enhanced quality control, improved site safety, and stronger environmental compliance.