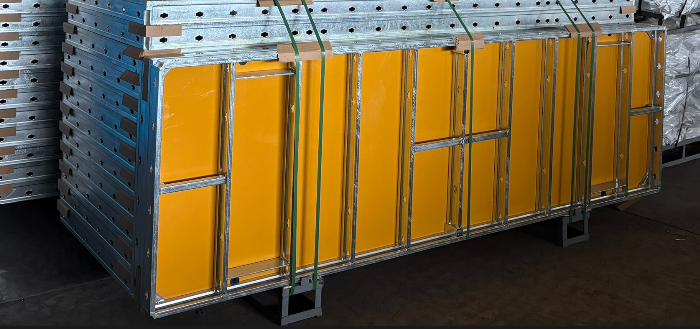

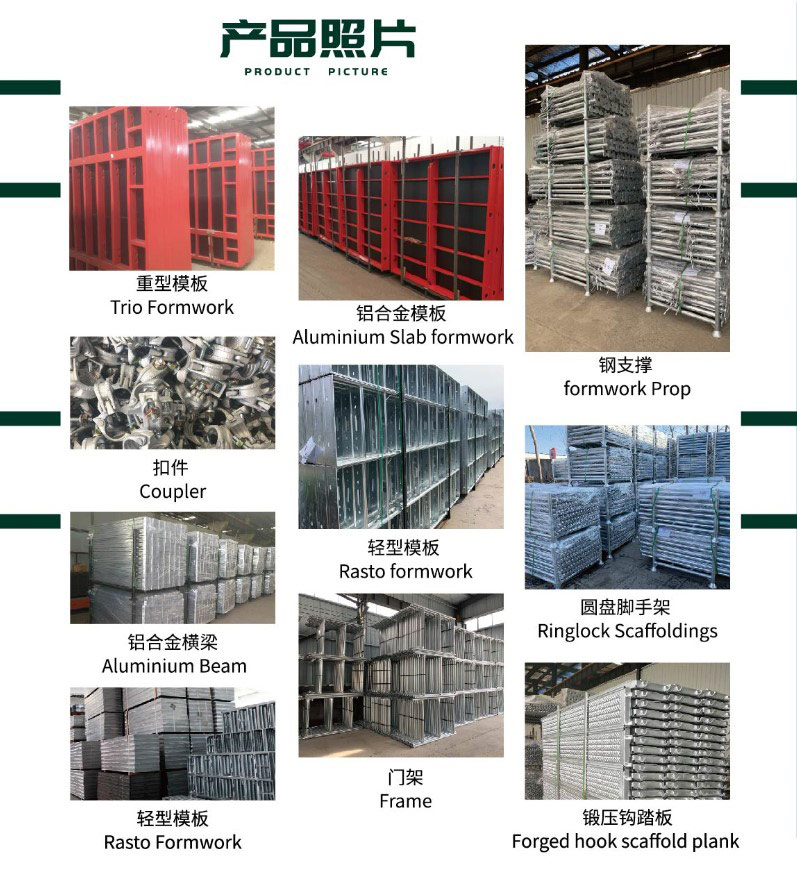

Concrete Ultra-Light Formwork Frame Panels Manufactuer

Advantages:

1.Long service life.

2.Easy and simple connections.

3.Birch plywood or PP Board and replaceable

4.Fast working operations

5.Large-area shuttering

6.Save time, Save money

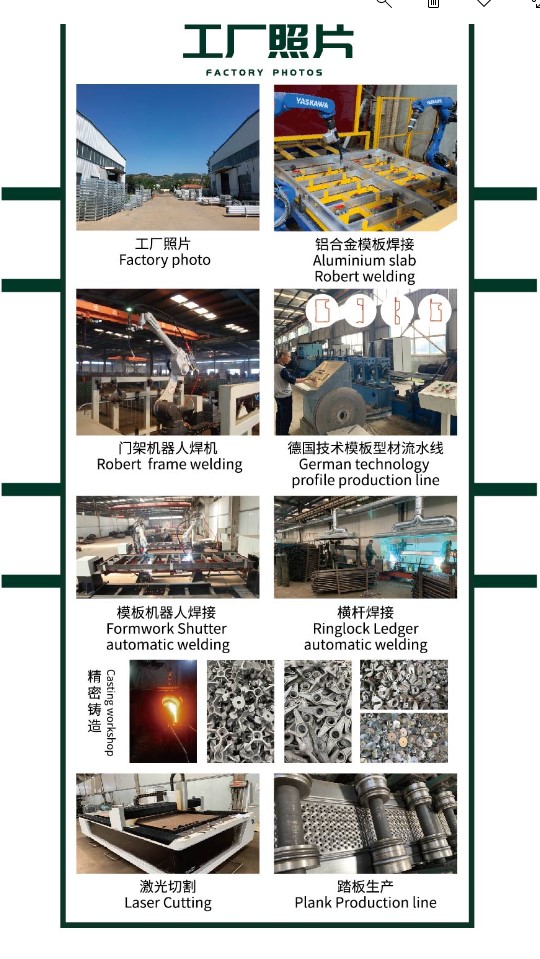

FENGHUA Ultra-Light weight steel Formwork

Ultra-light weight steel formwork is a modular formwork system that uses high-strength lightweight steel frames as the skeleton and pairs them with various panel materials. Its core design concept is "manually operable", aiming to reduce or eliminate the reliance on large lifting equipment (such as tower cranes), thereby enhancing construction flexibility, reducing costs, and accelerating progress.

Core Components

1. Steel Frame (Skeleton)

Material: High-strength steel (such as S420). This steel is of high strength and can be made lighter and thinner, achieving overall lightweight.

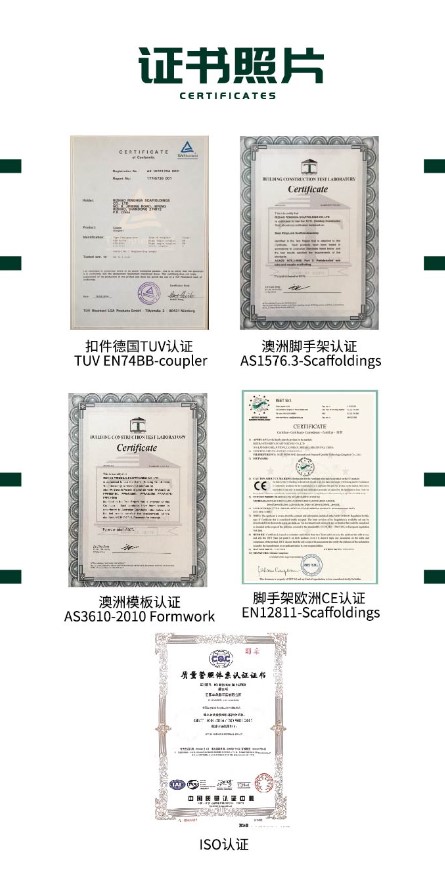

Surface Treatment: Hot-dip galvanizing. It provides excellent rust and corrosion resistance, significantly extending the formwork's lifespan and allowing for hundreds of reuses, making it highly economical.

2. Panel (Form Liner)

Birch Plywood: The most commonly used option. It has a smooth surface, is tough, and can produce a flat and high-quality concrete surface. High-quality laminated birch plywood has good water resistance and can be reused multiple times.

PP Plastic Sheet: A more durable choice. PP sheets are very smooth, do not stick to concrete, are easy to demold and clean, and are highly wear-resistant, with a lifespan far exceeding that of wood panels, capable of producing mirror-like concrete surfaces.

Key Features and Advantages

1. Ultra-lightweight and Manually Operable

Each formwork panel is light (typically two workers can easily carry and install it), which is its core advantage. It breaks the traditional limitation of large formwork systems that must rely on tower cranes, making it particularly suitable for projects with limited space or no tower cranes (such as low-rise buildings, basements, and renovation projects).

2. Fast Assembly and High Construction Efficiency

Simple and Reasonable Design: Modular design with standardized components, assembly is like "building with blocks".

Specialized Connectors: Such as the "self-aligning formwork connector" you mentioned, which can quickly align and fix the formwork, reducing adjustment and alignment time, and eliminating the need for additional reinforcement steps.

Flexible Tie Rod Options: Provides a variety of tie rod setting schemes, allowing workers to quickly adapt to specific structural characteristics and further shorten formwork assembly time.

3. Sturdy and Durable with Good Economy

Strong Structure: The high-strength steel frame ensures that the formwork system has sufficient strength and rigidity during concrete pouring, is not prone to deformation, and guarantees construction safety and quality.

High Reuse Rate: The hot-dip galvanized steel frame and durable panels (especially PP sheets) enable the entire system to be reused hundreds of times, with a very low cost per use, making it highly economical in the long run.

4. High-quality Concrete Surface Finish

Due to the high flatness of the steel frame and the quality of the panels, the system has good overall rigidity, resulting in a smooth, flat, and aesthetically pleasing concrete surface, reducing the need for subsequent plastering and other finishing work, and achieving a "raw concrete" effect.

5. Flexible and Wide Application

it is highly versatile and can be used for the pouring of various concrete structures such as walls, columns, and foundations.

It can be used for small, scattered components or connected to form large wall surfaces.

Typical Application Scenarios

1.Residential and Commercial Buildings: Especially for mid- and low-rise buildings.

2.Infrastructure Projects: Pipe corridors, bridge piers, retaining walls, etc.

3.Industrial Buildings: Factories, warehouses.

4.Renovation and Addition Projects of Old Buildings: These sites often have limited space, making it difficult for large equipment to enter.

Start your inquiry now. Hope to become your nice supplier in near futuer.