Aluminum Deck Formwork

Advantages:

1. Only panels and props for convenient and simple connection.

2. Birch plywood, replaceable

3. Quick work operation

4. Light weight, convenient disassembly

5. Safer: good stability, high carrying capacity

6. Concrete molding quality is good, long service life

7. Faster: More efficient, saves time and money.

8. Standardized panels for various structural buildings

9. Handheld design: Maximum size panel 1800 × 1800mm

Rizhao Fenghua Aluminum Deck Formwork

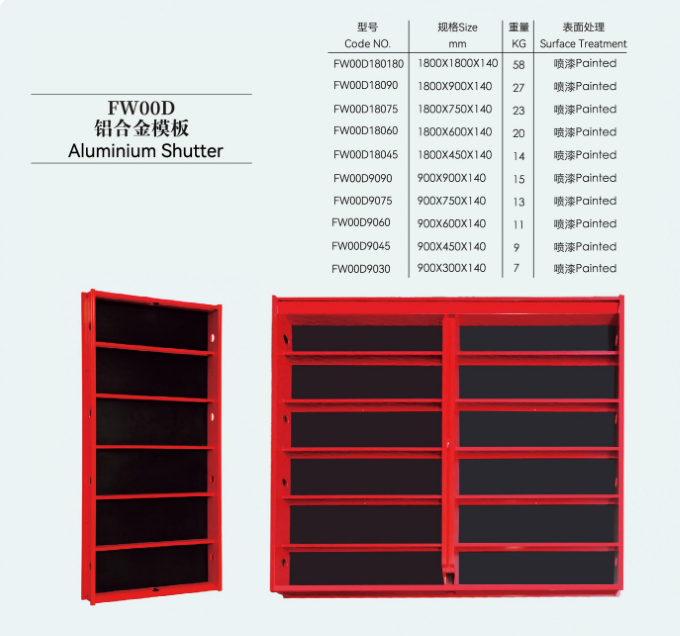

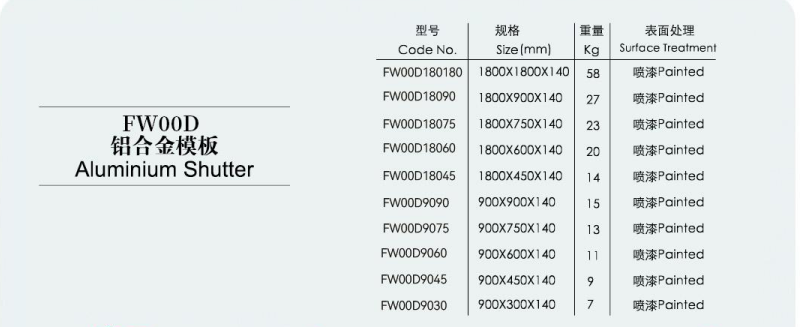

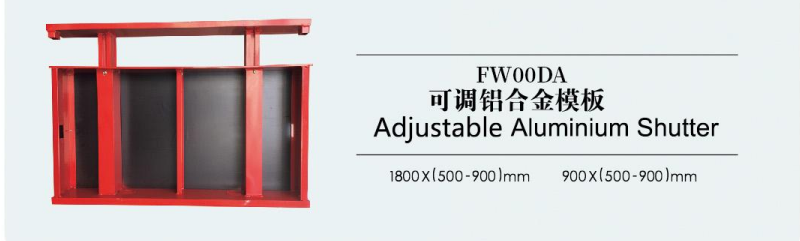

FW00D

For High-Rise Construction Efficiency

As China's premier formwork manufacturer since 1953, RFH has developed precision-engineered solutions tailored for the demands of modern high-rise construction.

The Aluminum Deck Formwork integrates aerospace-grade 6005-T6 aluminum alloy frames with 11 mm Baltic birch plywood panels,

bonded using phenol-formaldehyde resin to ensure exceptional structural integrity and long-term durability.

Certified Performance: Compliant with European Standards. it can be used together with topec.

Applications:

Widely used for flat slab or beam-less concrete project

Specification:

Standard:

European Standard

Sizes:

1800X1800mm 1800X900mm 1800X750mm

Other clients sizes are available.

Thinkness:140mm

Surface treatment: Alluminium Alloy

Packing and shipment:

Certificates:

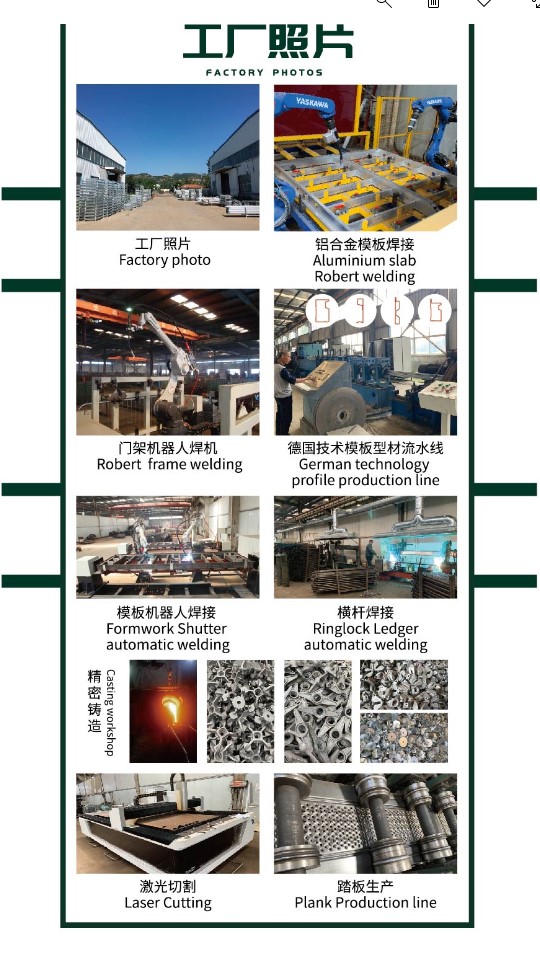

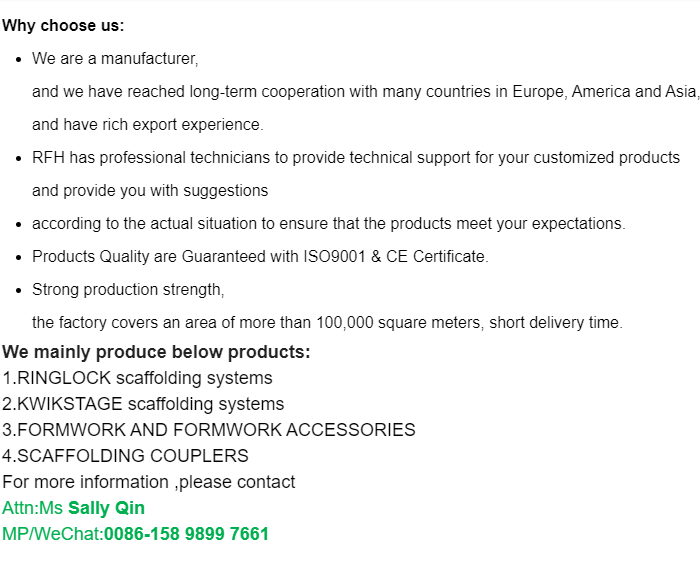

Factory Introduction:

Rizhao Fenghua Scaffoldings Co.,ltd. is a professional manufacturer and supplier of scaffolding systems and formwork systmes.

Founded in 1953, it's an old factory with a history of 70 years.

We produced and exported scaffolding systems since 1995 and produced formwork systems since 2012.

With rich production experience and advanced production equipment, it has passed the certificate of ISO9001:2000 quality management certification. EN74A AND EN74B standard ,CE Certificate:EN12811-1:2003, MPA NRW, Australian Scaffolding Certificate.

Factory show:

Fair show:

Now start your inquiry